2021-02-01

From the beginning of December 2020 to the end of January 2021, nearly two-month Yunnan Petrochemical Operation and Maintenance project was successfully completed.

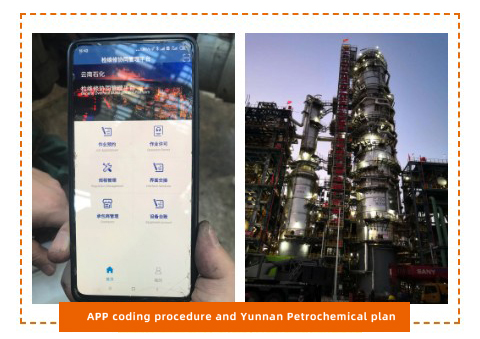

This Yunnan Petrochemical Operation and Maintenance project provided our company with a brand new experience in operation and maintenance management. In the major overhaul of Yunnan Petrochemical, new technologies and techniques were applied to boost the overhaul management with intelligence, digitalization and information technology.

To strengthen the fine management of overhaul equipment, more than 100 sets of dynamic equipment, 1,300 sets of static equipment, 2,900 sets of electrical equipment, 10,000 sets of instruments and 6,700 sets of constant torque fastening the points were labeled with metal tags and QR codes made of PET respectively. Like an ID card, the code is unique for each piece of equipment. Scan the QR code with a mobile app, this equipment’s code, model, name, specifications, technical parameters, maintenance history and other information can be seen at a glance.

The new maintenance management model of Yunnan Petrochemical requires us to be more standardized, and the different data entry methods have made the work more difficult.

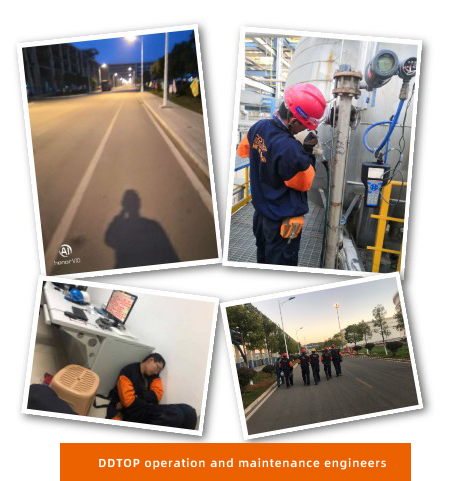

With limited staff, tight schedules and demanding maintenance projects, our instrumentation engineers had to work early and often in the dark every day, spending their days in Yunnan Petrochemical with the sun on their heads and the sun setting on their feet.

Even in the New Year, they did not go home to their relatives. Solving difficulties and tackling difficulties became their daily work.

From recording, uploading records, dismantling, inspecting, cleaning, repairing, counting, loading, shipping, installing and running, every step of the process is meticulous and rigorous, without a single mistake or problematic point being missed.

Whenever we walk under the dim street lights, the fatigue of the day comes to us.

Whenever we walk under the dim street lights, the fatigue of the day comes to our face, but whenever we solve a problem, the fatigue seems to be replaced by the pride in our heart.

Through more than 40 days and nights of hard work, we repaired a total of 512 displacer level transmitters, 18 float level transmitters, 14 magnetostrictive level transmitters and 120 magnetic level gauges in this Yunnan Petrochemical operation and maintenance project.

In a large scale operation and maintenance project, we have added another successful record for DDTOP.

The moment we received a letter of thanks from the customer, we were proud to be able to solve the problem for the customer and to be affirmed by the customer, and we felt that all the efforts and hard work were worthwhile!

In 2020, DDTOP Group participated in many operation and maintenance projects for large petrochemical enterprises such as Dalian Petrochemical, Tianjin Petrochemical, Jinxi Petrochemical, Yunnan Petrochemical, etc. “Highly Respect for Safety” makes our service and commitment a help to bring our customers a better life.

Let our service and commitment be a help to bring safe and good quality service experience to our customers.

您的瀏覽器當(dāng)前寬度低于1100px;請(qǐng)使用1300px以上寬度訪問(wèn)。